Fit out for The Mackenzie School of English, Edinburgh

The Mackenzie School of English is a language school for international 12 - 17 yr olds in Leith, Edinburgh and were moving to a bigger building just around the corner from their old place. The building is a converted Church with 3 floors. There was a considerable amount of fit out work to be done in this old building especially on the 1st and 2nd floor in order to divide the space into classrooms.

Fit out Mackenzie School of English, Leith Edinburgh

The main purpose of the move was to enable the school to grow and to offer a space that attracts students and is a pleasant place for staff to work. Now the MacKenzie School of English has one of the nicest and most inspiring teaching environment amongst their peers.

The building, originally called St John’s Church, was constructed in the late 18th century and redeveloped for office use in the early 1990s. The landmark listed building with its iconic stone Church tower in the centre of Leith has stood empty for a few years and came with a few surprises when our fit out team started on the demolition.

It proved to be both an interesting as well as difficult building to work on, but now it has all the infrastructure a state of the art school needs, such as CCTV, sound and projection systems, interactive screens, new electrics, fire safety measures, data cabling etc.

Using a basic lay-out drawing, the Amos Beech fit out team created full space planning, all construction drawings and organised the necessary building warrants. The kitchen was extended and new flooring was put down on the ground floor.

In the two images above you can see some of the construction work taking place while we were filming our company video to be introduced later this summer.

And that's why we like what we do:

Can't thank @amos_beech enough for all the hard work they've put in over the last few months. The new school looks incredible and we couldn't be happier. #work #dedication #newbuilding #construction #amosbeech #Edinburgh #Leith #Scotland #travel #studyabroad #learnenglish

— Mackenzie School (@MackenzieSchoo1)May 4, 2018

Office fit out and refurbishment Dundee

When Scotland's only tyre manufacturer asked us to draft a plan for their office refurbishment and fit out in Dundee, the team here at Amos Beech set out to transform the 40 year old building.

Office fit out and refurbishment for Michelin Dundee

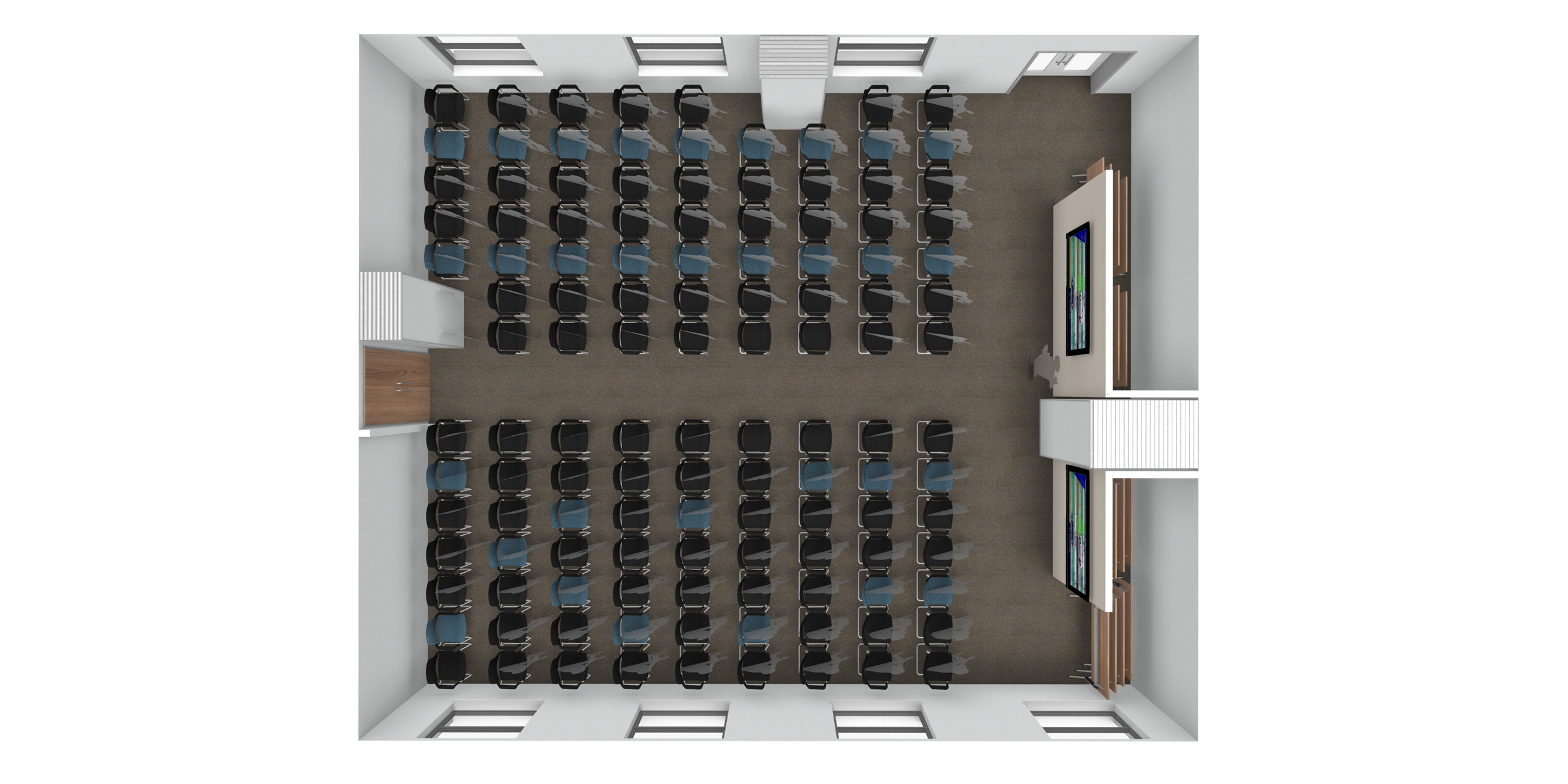

The Dundee plant has been transformed into a “state-of-the-art factory under the five-year investment programme. The Dundee factory opened its doors 43 years ago it is now the city's biggest industrial employer, with just 1000 staff. It manufactures more than seven million car tyres every year. The 'Bâtiment 10' or 'Building 10' hosts 70 office staff and every factory around the world has a 'Building 10' with office accommodation for similar office tasks.

Office fit out Dundee

The brief for this Dundee office refurbishment project

The need for this office refurbishment and fit out project in Dundee was clear from the outset. The building was old, uninspiring and even a depressing place to work. For a company of this stature, refurbishment was long overdue.

Michelin Dundee is Michelin’s best-in-class and is now topping the tables in efficiency and quality. Dundee was the first first Michelin factory in the world to embrace wind energy with two wind turbine generators helping to reduce environmental impact and energy bills.

It's standing attracts high profile visitors from across the world and needs an interior that you expect from a company like Michelin.

Also graduates were keen to start their career at Michelin, but the company struggled to keep staff on board. Michelin offers excellent training programs and career perspectives, but many talent left after a short period of time and when asked they mentioned the working environment was less then inspiring to say the least. You don't want that as an innovative and global company. After all “A better way forward” is the Michelin way:

The interior design and Lay-Out

The long rectangular building with cellular offices along corridors was to be transformed into a more open plan space with organic shapes. The desks were positioned off set from the walls and in the final design the wave desks were shaped nicely around the circular meeting pods.

Furniture specification

At Michelin 20 million euros are invested each year to develop new solutions for workstation ergonomics. Amos Beech have always been at the forefront of innovative seating and desking solutions and for this project sit-stand desking from Samuel Bruce, originally from Dundee was specified.

The days that working days were an important source for people's exercise are long gone for most people, especially for those that work in offices. Sedentary working applies to in between 4 and 6 hours per day in an average office and in total you are talking about 9 and 11 hours a day! A sit stand desk will bring in more variety in working posture during the day and reduces health risks. It also gives the flexibility in adjustment an international workforce like Michelin needs.

Changing between sitting and standing increases concentration and output which is essential for a best-in-class tyre manufacturing plant.

Office fit out project management

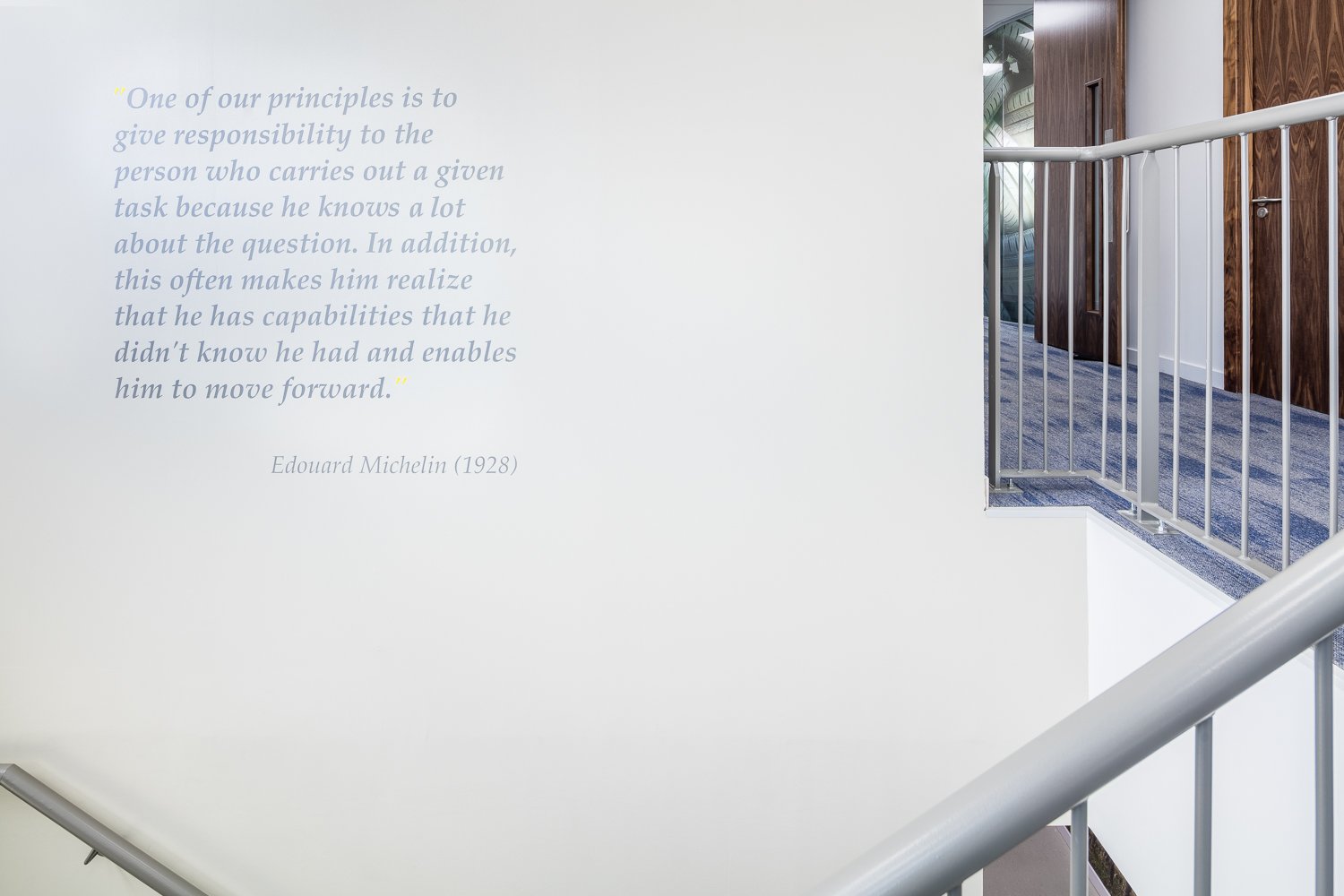

The office refurbishment was completed over two phases. We started on the ground floor and the initial works included the removal of part of the 1st floor to open up a more impressive staircase entrance reception area. A new staircase was manufactured to the designers specifications and all internal doors were replaced.

As the project was underway it was decided to build an entrance vestibule in front of the reception and despite the already tight time frame, this had to be completed within the timescales allowed.

Walls were opened up and replaced with glazed partitions to allow light to flood through the interior. These new glass partitions have been subtly branded with the iconic Bibendum and other Michelin marketing images.

The overall interior design scheme takes full cognisance of the Michelin brand and uses the approved branding colour palette to establish the Michelin identity whilst retaining a sense of belonging for the individuals who work in the space.

When the second phase started, we had to remove from the building a large safe that had been built in originally. Heavy lifting equipment and careful health and safety planning allowed this to happen without delays or damage to property or person.

As part of the overall scheme, all external single glazed windows were replaced by new double glazed units to improve the thermal efficiencies of the building and the heating and ventilations system was similarly upgraded to meet with the current standards.

The end result is a refreshing and modern interior which is already making a huge difference to the first impressions given to visitors on arrival. Going forward the Michelin management team are confident that the investment will reap rewards in terms of productivity and staff satisfaction.

Publication date: April 11th, 2017

The office in the Blyth Building is currently in use as part of the Michelin Scotland Innovation Parc, after Michelin closed it’s operations in Dundee.

Text: Sam James

Photography: Architectural Photographer Edinburgh

Moving glass wall for WH Malcolm Glasgow

When the Malcolm Group contacted us, asking if we could advise them in replacing a balustrade for a glass wall, in the Donald Malcolm Heritage Centre just south of Glasgow we were keen to get to know the place.

The Heritage Centre was built by Andrew and Walter Malcolm in memory of their father, Donald Malcolm. Donald started the company in the early twenties with a single horse and cart. It was a small family-run business that collected coal from the railway station and distributed it around the local area. Today the Malcolm Group is a large logistic services company active in road and rail transport, warehousing, and terminal management.

A great place for truck lovers and petrol heads!

Movable Glass Wall Glasgow

The beautifully made balustrade that had to be replaced with glass was an excellent example of craftsmanship, but it unfortunately meant that the whole museum had to be heated when the meeting room was in use. At the same time Malcolm wanted to maintain the open connection between the meeting hall and the exhibition centre.

The removable wall starts left from the entrance door in the picture above or right in the picture below.

Our fit out team were excited at the prospect of working in this great environment and also the photographer (a diesel head himself) was chuffed to bits when he learned where he was going. The story of W H Malcolm is inspiring and to have the privilege of working here ticked all the boxes.